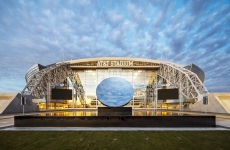

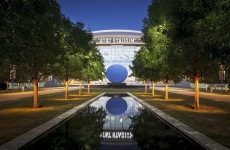

Some projects carry obvious prestige, and this is one of them: The pair of reflecting pools and the sculpture that rises above them stand in front of AT&T Stadium in Arlington, Texas – home to the Dallas Cowboys and, several times a year, host to nationally televised football games.

But certain of these prestige projects take on extra dimensions – and this was one of them, too: The mirror-finished dish that surmounts the watershapes (for which we at Roman Fountains of Albuquerque, N.M., designed and manufactured the equipment and control systems) now reflects the huge skies of Texas and effectively kicked our work up to a cosmic scale.

Another feature that made this project unique was the combination of haste and secrecy involved in pulling it together – a swift trip along the path to success.

Surprise!

The project was initiated at the request of the wife of Jerry Jones, owner of the Cowboys and a man with an outsized, Texas-scale personality. She’d purchased “Sky Mirror” – by India-born sculptor/current London resident Sir Anish Kapoor – as a surprise gift for her husband.

Her goal, we learned in June 2013, was to have the entire composition of sculpture and reflecting pools ready for unveiling in front of the stadium on Sunday, October 13, when the Cowboys were to host their great rivals, the Washington Redskins. It would also be Mr. Jones’ birthday – and everything in this very public space had to be handled in such a way that he wouldn’t know what was coming.

Given the brief time to completion, we knew we had to have our mechanical and control systems completed, shipped and ready for placement quickly. This need for speed took what might have been a fairly straightforward project and complicated it considerably: Instead of months for systems development, assembly and testing, we had weeks – and what we produced had to be fully ready to go, basically in plug-and-play form.

On our end, in other words, it was a superfast-track project – no room for errors or delays.

The reflecting pools were quite significant because they served as a visual extension of and foil for the mirrored sculpture. This led the designers to specify in black so far as materials were concerned; for our part, we had to do all we could to deliver water to both basins with an absolute minimum of turbulence to enhance their surfaces’ mirror effect.

The rectangular top pool serves as the sculpture’s foundation and overflows into a much larger lower basin. The lower pool, in turn, overflows on four sides into a narrow, grated catch basin for storage and recirculation. The nominal thickness of the sheet of water flowing smoothly over the walls was to be approximately 3/8ths of an inch, meaning a large volume of water had to be added to the system on the lower level – again without turbulence.

Familiar Components

All of this would have been quite direct and much easier to accomplish had the construction timeline been anywhere close to normal. In this case, however, the clock was always ticking urgently.

To speed up the process and minimize on-site activity, we recognized that the system we devised would have to be based on tried-and-true components, starting with our RDP Series 5 direct-burial equipment vault. This structure is approximately 15 feet long, eight feet wide and nine feet tall and, once equipped, weighed in at approximately six tons. It featured a 36-inch-square hatch – in this case a special traffic-bearing model as the vault was to be buried under an active fire lane.

By the time we were ready to ship it to the job site, the compact vault had been well stocked by Rob Astorga, Roman Fountains’ operations/production manager, under the direction of Wayne Pierce, the company’s lead designer and engineer for the project. The package included two 1,400 gpm variable-frequency-drive pumps to allow for fine-tuning of the output volume of the circulation system. In addition, we tied the pumps to a wind detection/compensation system that either ramps down the flow or cuts it off entirely to cope with any significant wind events.

The filtration system features a pair of permanent-media sand filters, each equipped with its own two-horsepower pump and multiport valve controller. To keep the water safe and clear, we included twin commercial-grade copper/silver ionizer units as well.

For purposes of the unveiling, we outfitted the vault with a stand-alone fountain-control system. Once the dust settled and everyone was breathing easier after Mr. Jones’ birthday, we went back and upgraded everything to allow for remote system monitoring and control through the stadium’s own facilities.

A Blur of Activity

In ordinary circumstances, assembling and testing such an array of equipment would have taken two or three months as we advanced from design approval to delivery. In this case, we focused on known solutions and essentially cut the time in half, preparing the vault and its contents for delivery to the site for immediate installation by the team at Water+Structures of North Richland Hills, Texas.

That company’s president, Bryan Weber, had brought the project to us based on our having worked together in the past. Because of this history, we at Roman Fountains didn’t hesitate and began working on June 28 – well before any contracts were signed. In fact, that formality didn’t take place until July 17, but by that point we were many steps along in the process and delivered our completed design drawings on July 18.

Production began early in August; the fully tested vault package was shipped September 3. Five weeks later, all work on site was complete, Mrs. Jones made her presentation and the whole affair was televised on the local news. Perfecting the celebration was the fact that Dallas beat Washington that evening.

It was a rush, no doubt about it. But from the start, communications channels were wide open; everyone knew exactly what had to be done and by what deadlines; and success was the only objective. In this case, looking at the beautifully situated sculpture, it’s easy to conclude that the sky literally was the limit.

Jon Mitovich is past president and senior advisor to Roman Fountains Corp., with headquarters in Albuquerque, N.M. The company works worldwide as consultants, designers, manufacturers and installers of fountains and other watershapes.